Description

Designed primarily for use in the oil and gas industry, differential pressure recorders are also ideal for monitoring flow, filtration, and liquid levels. Differential Pressure Recorders are sometimes called Orifice Recorders.

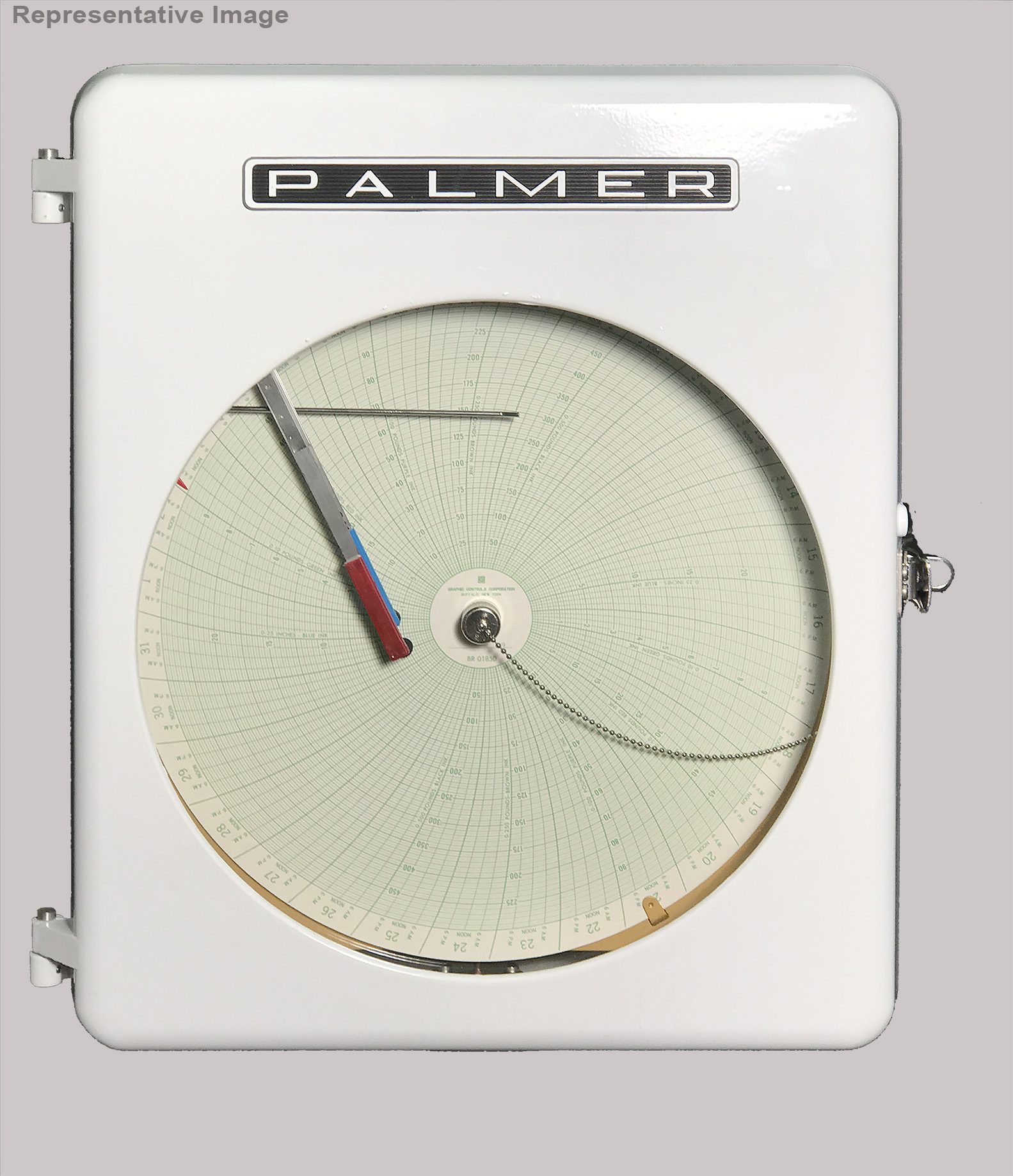

Palmer Differential Pressure Circular Chart Recorders are durable, fully mechanical units with a low maintenance design. Our Model 524 Differential Pressure Recorder incorporates an edge welded rupture proof pressure cell for up to 30% added lifespan and greatly improved linearity.

The heavy aluminum, die cast and powder coated cases are all-welded construction to prevent deterioration are available in 12 inch chart sizes. Palmer Differential Pressure Recorders has a 9-7/16 inch arc line and are fully compatible and interchangeable with the famous maker model charts.

Available with up to 3 pens: one differential pressure, one static pressure, and one temperature.

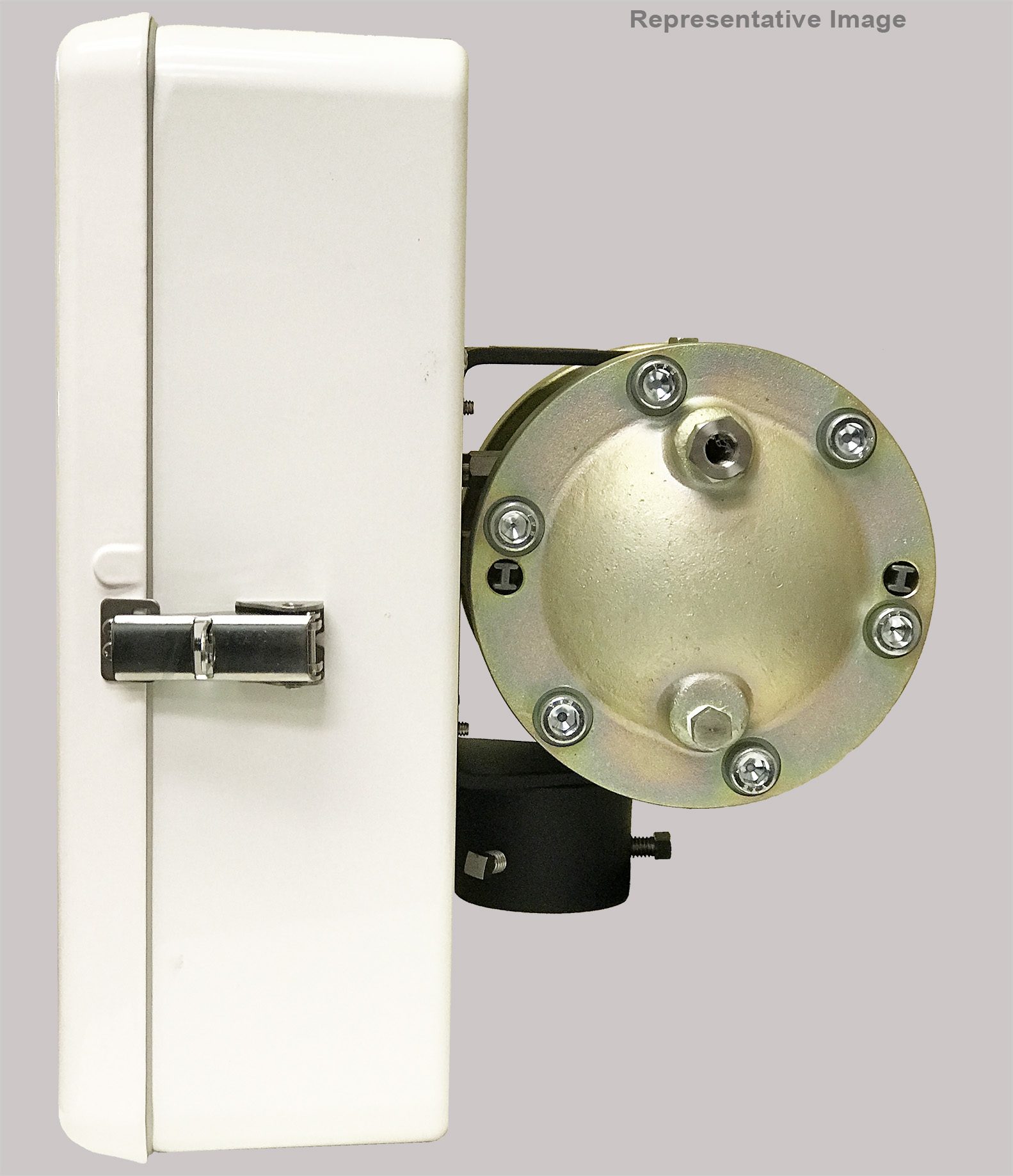

Pipestand mount only.

Our circular chart recorders are built with weatherproof construction, including a heavy lockable door with weatherstripping, with or without a window. Designed for outdoor use, the rugged design withstands high levels of vibration and includes one-half inch screened air vent holes in the case, adjustable door pull latch with available locking hasp, all stainless steel corrosion resistant internals, and micro-adjustable wire linkage.

Low pressure elements for ranges 30 PSI and below are 316SS bellows diaphragm, tubing, and fittings. Standard pressure elements for ranges over 30 to 10,000 PSI are made from 316SS helical coil with stainless steel fittings and tubing, and have 1/4 inch NPT fitting. High pressure elements for ranges above 10,000 PSI are made from 316SS bourdon tube with autoclave fitting. High pressure elements are calibrated on the rise only.

All temperature systems for Differential Pressure recorders are Mercury Free. Temperature ranges up to 600°F are available, with 10 feet of capillary standard. Choose from our available Non-Toxic or Hydrocarbon Fill temperature bulb configurations.

Choose a recorder drive to configure your recorder. Our most popular option is the PC-11 C-Cell battery powered, eleven speed motor with speeds of 60 minutes, 96 minutes, 12 hours, 24 hours, 48 hours, 7 days, 8 days, 14 days, 16 days, 31 days or 32 days. Our PC-12 C-Cell battery powered, twelve speed motor offers speeds of 30 minutes, 60 minutes, 2 hours, 4 hours, 6 hours, 8 hours, 12 hours, 24 hours, 3 days, 4 days, and 7 days.

Palmer Differential Chart recorders use scannable disposable fine point felt tipped pens. Standard pen colors are DP - Red, Static Pressure - Blue or Black, and Temperature - Green. *Please note that differential recorders use AR-3713 series pens. Contact us for help in selecting the correct chart for your application.

All Palmer Circular Chart Recorders are built to order in our Asheville, NC factory.